Project Story 05 Source of The Nile Bridge

Source of The Nile Bridge East Africa’s first cable-stayed bridge constructed by an international team

The Nile River, one of the longest rivers in the world, flows north from Lake Victoria in Uganda across the African continent and empties into the Mediterranean Sea at Alexandria, Egypt.

The Source of The Nile Bridge, East Africa’s first cable-stayed bridge, was built 2.5 km downstream of Lake Victoria at the uppermost reaches of the Nile, at the “Source of The Nile.”

This bridge was constructed as part of the Japanese government’s ODA loan project by an international team led by a joint venture between our company and a Korean firm. It opened in October 2018.

The opening of this bridge at the “Source” of the Nile is expected to make a significant contribution to the improvement of logistics and transportation in East Africa.

Features

Constructing the largest concrete

-girder cable-stayed bridge

by a Japanese company in Africa

Constructing the largest concrete

-girder cable-stayed bridge

by a Japanese company in Africa

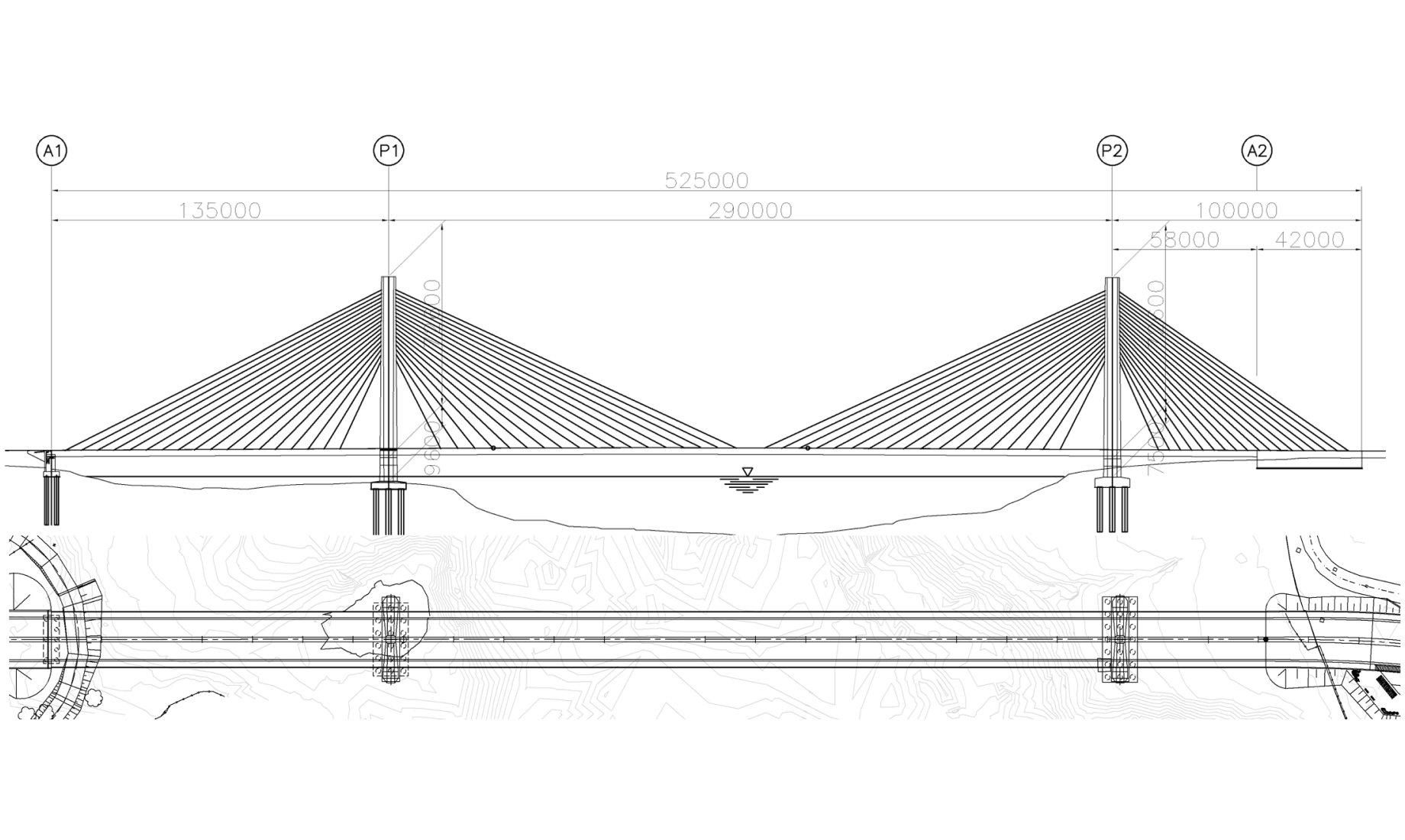

The Source of The Nile Bridge is a three-span continuous cable-stayed bridge with a total length of 525 meters and a main span of 290 meters. Both the main tower and main girder are constructed of concrete, and this bridge is one of the largest cable-stayed bridges with concrete girders ever built by a Japanese company, even including projects within Japan.

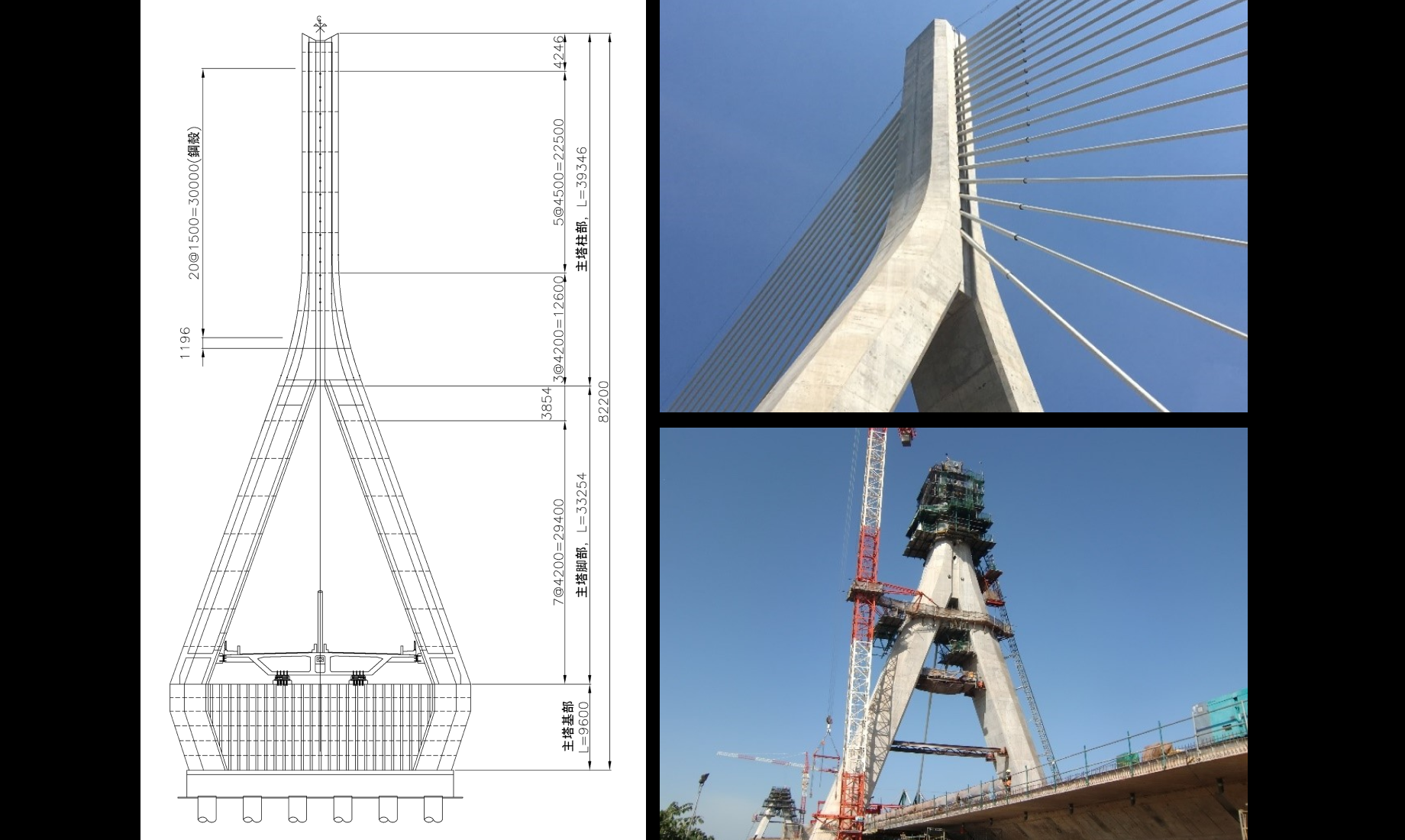

The structure type of this bridge, a cable-stayed bridge, suspends the girder using cables stretched diagonally from the tower. The Source of The Nile Bridge employs an inverted Y-shaped main tower approximately 80 meters in height. From this main tower, 18 cables extend to both the left and right sides, suspending the concrete girder. During the construction of the main tower, an elevator capable of moving along its curved shape was installed to facilitate the work.

Spanning the Nile River

Cantilever construction performed without

erecting scaffolding in the river

Spanning the Nile River

Cantilever construction performed without

erecting scaffolding in the river

While the main tower extends vertically, the bridge girder extends horizontally and was constructed using cantilever construction with a large form traveler. Cantilever construction is a method in which the girder is extended forward from the already completed end, eliminating the need to erect scaffolding in the river. The form traveler used in construction also moved forward in sequence as the girder extended, allowing construction to progress.

Eventually, the left and right girders meet in the center and are joined in a “closure” to complete the girder construction. Before the closure, the form traveler is usually dismantled; however, for this bridge, plastic drums were attached to the form traveler as floats, and it was lowered onto the Nile, floated, and towed to the shore for dismantling.

After the closure, cable tension was adjusted, the bridge surface was paved, and railings and lightning protection equipment were installed. Finally, a “load test” was conducted to confirm the deflection under load. In the load test, dump trucks loaded with soil were lined up on the bridge to confirm that deflection was within the expected range.

Looking Ahead to the Next 120 Years

A Bridge for the Future of Africa

Looking Ahead to the Next 120 Years

A Bridge for the Future of Africa

The Source of The Nile Bridge was opened in October 2018, following a construction period of over 4 years and 8 months that began with the groundbreaking ceremony in January 2014. The opening ceremony was held in grand fashion, attended by President Yoweri Museveni of Uganda, then Japanese Vice Minister for Foreign Affairs Masahisa Sato, Japanese Ambassador Extraordinary and Plenipotentiary to Uganda Kazuaki Kameda, over 2,000 invited guests, and more than 5,000 local residents.

The bridge is designed for a service life of 120 years, and a wide variety of sensors have been installed throughout the structure to ensure long-term structural health and facilitate proper maintenance. In addition to these physical features, support was also provided for the preparation of operational manuals for the Uganda National Roads Authority and for the training and education of engineers in monitoring techniques, ensuring continued maintenance from both tangible and intangible perspectives.

As the largest bridge in East Africa spanning the Nile River, one of the world's longest rivers, we sincerely hope that it will continue to contribute to the economic development of the East African region for many years to come.

Source of The Nile BridgeSource of The Nile Bridge

Project Overview

-

- Construction Site

-

Jinja District, Republic of Uganda

-

- Client

-

Uganda National Roads Authority

-

- Construction Supervision

-

Oriental Consultants (now Oriental Consultants Global) / Eight-Japan Engineering Consultants / Pyunghwa Engineering Consultants JV

-

- Construction

-

The Zenitaka Corporation / Hyundai Engineering & Construction JV

-

- Construction Period

-

January 2014 - October 2018

-

- Project Overview

-

Three-span continuous cable-stayed bridge

Bridge length : 525.0 m

Span lengths : 135.000 m + 290.000 m + 100.000 m

Effective width : 22.900 m - 23.540 m

Main tower height : 69 m above the bridge deck (approx. 80 m above the top of the foundation)

Main girder cross-section : triple-cell box girder

Stay cables : single-plane arrangement (18 pairs)